Whatever it takes to finish things, finish. You will learn more from a glorious failure than you ever will from something you never finished.

Neil Gaiman

In this post I will briefly summarize the finishes used, mistakes made, and latest improvements to “Moby-Dick; or, The Toolchest.”

The Original Finish – A Tale of Woe

More than 26 years ago when this toolchest was new, your humble servant applied a rubbed-out catalyzed lacquer finish inside and out which showed the grain pattern and color of the wood nicely, but proved to be less-durable than I had anticipated. I refinished the chest once, but after years of rough use, many moves over many years, and painful encounters with trucks, shipping containers, forklifts, and one-legged meth-head moving company employees, the finish was in poor condition. I concluded that lacquer, varnish and even polyurethane do not really qualify as durable finishes for a piece of working casework with a target useful lifespan of 200 years, at least if it’s not to be pampered like a baby grand piano in grandma’s drawing room.

Exterior Refinish

While living on the Pacific island of Guam in 2011 and with free time on my hands due to international political corruption (difficult to imagine huh (ツ)), I gazed upon my toolchest and despaired for, yea verily, it was in bad shape, cosmetically that is, covered with scratches, dings and gouges topped off with yellowed, crazed and crumbling varnish. It had been a good and faithful servant for many years and deserved better so I girded up my loins, scraped and sanded off the old finish, leveled the scratches, dings and gouges with auto body filler, and refinished it.

When considering how to refinish my toolchest in a way that would provide improved UV and abrasion resistance while also concealing past external cosmetic damage, I was intrigued by an article in a woodworking magazine by Mr. Michael Dunbar about milkpaint. Mr. Dunbar is a wise and retired professional Windsor chairmaker, not just a scribbler, so I take what he writes seriously.

I removed the old varnish finish inside and out and, following Mr. Dunbar’s recommendation, applied multiple coats of red, green, and dark, almost black, burgundy-colored milkpaint to the bare exterior wood surfaces. I then sanded and distressed the paint to expose the various color layers, and applied one coat of thinned clear Epifanes flat polyurethane as a protective topcoat. This was a 2 week process.

This milkpaint finish has proved effective not only in concealing past cosmetic damage and the Bondo used to repair it, but at the time these photographs were taken it had endured one international move by ship, two local moves inside Japan by truck, and months banging around inside hot humid shipping containers and dank warehouses since it was applied. It has only improved with age and abuse. Thank you Mr. Dunbar.

Milkpaint is an interesting material. It is non-toxic, which is nice when applying it. It doesn’t out-gas toxic compounds into the air either which is even nicer.

It has a water carrier with mostly mineral solids instead of volatile resins, so when cured it forms a hard, abrasion-resistant, non-shrink, no-peel surface unaffected by UV light, unlike latex, lacquer, varnish, and polyurethane.

The user can mix most any color they want using the available powders providing an endless palette.

It’s easy to use, forgiving and doesn’t take special tools to mix and apply, just glass jam jars, stirring sticks, strainers, paintbrushes, sandpaper, an old blender, and paper shopping bags.

Milk paint makes possible an easily-applied, inexpensive, tough, UV resistant, non-toxic surface finish with an antiquish, unique appearance that not only resists damage but even improves with time and abuse. What more could you possibly want? Egg in your beer?

Interior Refinish

I refinished the toolchest’s interior surfaces with shellac to eliminate the stink of curing resins. Time will tell how well it holds up, but so far so good.

Conclusion

My toolchest is far from perfect, but it meets all my performance criteria and works pretty darn good for me.

If I were to do it over again, I’m not sure I would change the current design or finishes, other than the way tools are mounted inside the lid. Compared to the original design, the current arrangement is more functional, but there is always room for improvement.

I think the most important thing this series of articles about toolchests has to offer is not the design itself but rather the performance criteria developed and the decision process that led to the design and ultimate construction.

As I mentioned in Part 5 of this series, there are many decisions that must be made when planning a tool storage system. I hope you, Gentle Reader, got my point that you can either take the time and make the effort to plan, or neglect to do so and let the decisions be made through default and happenstance whirling down and around the porcelain scrying bowl of chance. Either way, the decisions will be made.

Perhaps reading the performance criteria and seeing the design and execution of this toolchest will stimulate your planning. Many of your requirements will be the same as mine, but others will be different, so the solutions and design details you employ will be different too. At the very least you now have a detailed, practical example to reference when planning storage solutions for your valuable tools.

I hope Gentle Reader also noticed how tradition can provide solutions to universal challenges of tool storage, but that through careful consideration you can improve on tradition to best meet your specific needs.

In the next and final post in this series I will explain how “repairability” was incorporated (or not) into the design.

YMHOS

If you have questions or would like to learn more about our tools, please click the “Pricelist” link here or at the top of the page and use the “Contact Us” form located immediately below.

Please share your insights and comments with everyone in the form located further below labeled “Leave a Reply.” We aren’t evil Google, fascist facebook, thuggish Twitter or the Congressional IT department of the Democrat Party and so won’t sell, share, or profitably “misplace” your information. If I lie may every piece of paint I touch turn to lead, curl and crumble.

Other Posts in this Series:

- Toolchests Part 1 – And Away We Go

- Toolchests Part 2 – History

- Toolchests Part 3 – Pros & Cons

- Toolchests Part 4 – Goals & Objectives

- Toolchests Part 5 – Formulating Performance Criteria

- Toolchests Part 6 – Key Performance Criteria Solutions 1 – Durability & Longevity

- Toolchests Part 7 – Key Performance Criteria Solutions 2: Sealing, Insulation, Security, Portability & Tie-down

- Toolchests Part 8 – Under the Lid

- Toolchests Part 9 – Trays

- Toolchests Part 10 – The Dungeon

- Toolchests Part 11 – The Bottom

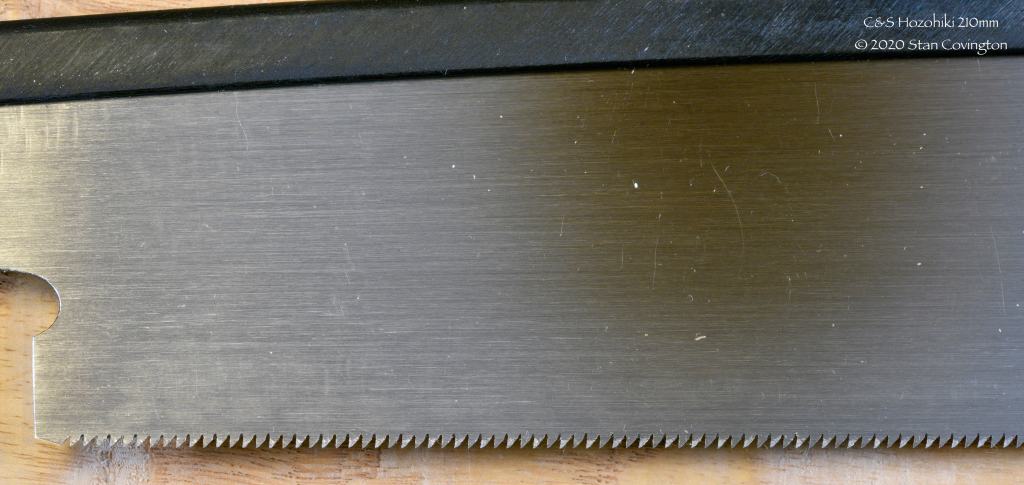

- Toolchests Part 12 – The Sawtill

- Toolchests Part 13 – Finishes

- Toolchests Part 14 – Repairability

Leave a comment