The gentle reader will never, never know what a consummate ass he can become until he goes abroad. I speak now, of course, in the supposition that the gentle reader has not been abroad, and therefore is not already a consummate ass. If the case be otherwise, I beg his pardon and extend to him the cordial hand of fellowship and call him brother. I shall always delight to meet an ass after my own heart when I have finished my travels.

Mark Twain, The Innocents Abroad

In the previous post in this series we discussed the various styles of gennou heads you might consider when planning a custom-made gennou that fits your body perfectly, as well as the range of weights for each application.

While one has few options besides either using a mass-produced head or making one yourself nowadays, in Japan there are still a few blacksmiths that specialize in hand-forging high-quality gennou hammer heads. In this post we will compare mass-produced heads and hand-forged heads to help you make an informed decision.

Comparing Mass-produced Heads to High-quality Hand-forged Heads

When selecting a gennou head you have the choice of a mass-produced gennou (usually with a handle attached) or a handmade gennou head without a handle, if you can find one. Lets examine the differences.

Mass-produced genno are readily available, relatively inexpensive and for the most part, entirely useable. However, as with any product, it is wise to inspect a gennou carefully before purchasing it, as discussed in a previous post in this series, or to at least buy from a retailer with a solid return policy. When purchasing any gennou, check to make sure the eye is centered in the head and not skewed.

The practical advantages of a hand-forged gennou hammer head over a mass-produced factory head are as follows:

- Proper differential hardness;

- Precise eye placement;

- Uniform interior dimensions of the eye, resulting in time saved and aggravation avoided when fitting/refitting a handle;

- Faces are square with the long axis of the head;

- Improved Performance due to more uniform distribution of mass providing improved stability during the swing with fewer wiggles, more solid strikes, and fewer off-center hits.

- Unique appearance and pride of ownership.

Let’s examine these points in more detail next.

Heat Treatment

Most Gentle Readers will have never given this matter any thought, but the quality of the heat treatment matters… a lot. This is a chemical/crystalline property impossible to confirm long-distance, so we must rely on the manufacturer, be it factory or blacksmith, to get right. Therefore, the manufacturer’s QC reputation as well as the retailer’s guarantee also matters.

A good head will be hard at the faces, becoming gradually softer towards the the eye, certainly softer than a file, to make the head “tougher,” using the materials engineering term, and to reduce resonant harmonic vibrations. If you have used hammers with uniformly hard heads and integral steel handles you have felt this tiring vibration before.

The faces must be hard, around 50~55Rc, to prevent deformation, but not so hard the hammer will chip or crack. You may think that wooden chisel handles could not deform a steel hammer face, but if the striking faces are not properly hardened, they will mushroom sure as eggses is eggses, something your humble servant learned when he made a gennou head for himself from unhardened octagonal steel bar stock back when dinosaurs roamed the earth.

It’s interesting to note that the handle I made in days of yore was straight, unlike the handles your humble servant currently advocates, and that lower 1/3rd of the face (closest to the hand) mushroomed, while the upper 2/3rds did not deform at all. Curious…. This was the first time I really noticed that the head of hammer with a straight handle attached perpendicular to the head’s centerline tends to hit the chisel/nail cocked and not in-line with the long axis of the chisel/nail. I also realized that the direction of flow of this steel indicated a lot of energy was being wasted by my straight handle. I hope you can see why the solution the anaya carpenters of Japan developed so long ago resonated with me so strongly.

But what happens if the heat treatment results in a head that is too hard? In this case, while the head and faces may not deform, the face may chip and the entire head may fracture, sometimes even causing embarrassing leakage of sticky red stuff (or at least that’s what the product liability lawyers assert).

A word to the wise: always use properly heat-treated hammers and wear safety glasses when pounding nails, mixing acid, or writing your name on your forehead with ballpoint pen after losing a tequila shot contest.

Precision of the Eye

Gentle Readers may think it passing strange that your most humble and obedient servant is seemingly fixated on the precision of something as boring as the hole in a hammer’s head. Rest assured, this concern is not a fever dream resulting from an obsessive/compulsive over-analysis of negative space, but was born of bitter experience. My new therapist concurs.

Of all handtools, the hammer is one of the simplest. But is also the one that moves the fastest and is most influenced by dynamic physics. Things like concentricity, center of gravity, and moment of inertia make a difference to an object moving this quickly, then suddenly slowed by an impact with a chisel or nail, and then returned to battery for another blow faster than you can say “ouch.” Negative spaces like holes influence the physics, and therefore the stability, of hammer heads. Don’t make me inflict you with differential equations, just take my word the hole needs to be centered, not skewed, and of uniform size or the hammer will be skittish resulting in twisted mortise holes, bent nails, and maybe even smashed thumbs.

Another advantage of a well-made gennou head is that its eye will have uniform interior dimensions. We talked about this in an earlier post. In summary, all four walls will be straight, clean, flat, free of wind, parallel and square to each other. This matters because a sloppy eye will not apply uniform pressure on the handle’s tenon, ensuring it will come loose sooner than later. In addition, this uneven pressure may also induce unwanted vibrations in the handle.

If a gennou head has a sloppy eye, it needs to be trued, a task that is difficult to accomplish using files. Depending on the degree of error, correcting the inside walls of that tiny hole in a steel head with skinny files can be frustrating work and may even help your own therapist buy that new bimini top he wants for his fishing boat. You see, most people make the problems worse the first time they try to correct them. I know I did. If you count your time worth anything, the extra cost of a precision eye is money well spent, and certainly cheaper than a Rolex for your therapist’s girlfriend.

Precision of the Face

Let’s move on to item 4 “Faces are square with the long axis of the head.” The striking faces of mass-produced hammer heads are often not square with the head’s axis (i.e. manufactured 90˚ to to the head’s longitudinal axis) resulting most obviously in bent nails, but the less obvious consequence is that energy we intended to transmit directly to the chisel and into the workpiece ends up being wasted as heat and violent movement of the chisel out of alignment. It also wastes time and undermines the user’s confidence, once again providing a windfall to head doctors everywhere. A precisely manufactured face square to the tool’s centerline will yield better static performance and more precise chisel work and nail bashing than a mass-produced head.

The hammer that is stable during the swing and makes a solid impact exactly where you aimed it without producing strange vibrations or wasting energy will help you make every strike with confidence and greater control, and will make your woodworking more enjoyable and profitable. Not insignificant benefits.

Improved Dynamic Performance

In addition to the advantages described in the previous paragraph, a hand-forged head, if made correctly, will be more stable during the swing, and wiggle less upon impact because its mass is more uniformly distributed. This means fewer misses and more energy transmission on impact. And that’s the whole purpose of a hammer, right?

A hammer made using a good head and a handle made to fit both that head and your body will perform better than any tool you have experienced before. You won’t need to look when you pick it up to tell which face (or claw/vs face) is oriented towards the nail/chisel because your fingers will know instantly. The handle will fit your hand perfectly without slipping or causing blisters or needing to be “choked-up on.” You will be able to sense beforehand exactly where the center of the hammer’s face will strike, and will be able to hit the target dead-center and squarely even with your eyes closed.

Appearance and Pride of Ownership

And finally, let’s examine the more ephemeral item 5: “Unique appearance and pride of ownership.” I have mentioned it elsewhere before, but it is a fact that, no matter how much they may deny it, humans are competitive beasties in all endeavors.

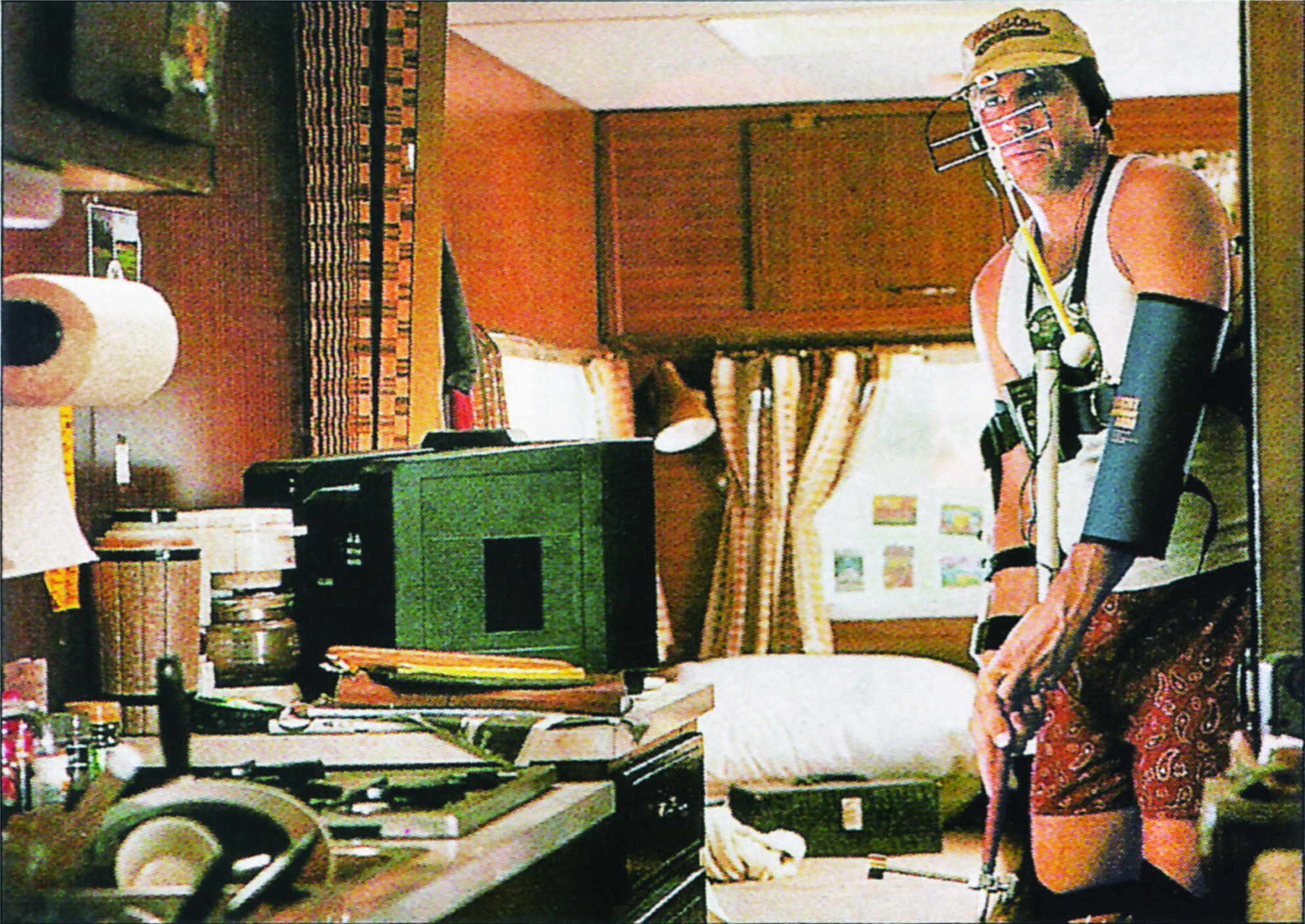

As a day job your humble servant manages construction projects in Japan and spends a lot of time inspecting jobsites, meeting with construction companies and speaking with craftsmen. Indeed, there was a time when I was labor instead of management on construction jobsites, so I have enough experience to know that, while some professional woodworkers may not read fashion magazines with titles like “Amazing New Toolbag Design that Will Lift and Shape Your Butt” during coffee breaks, or wear sleek, handmade calf-skin steel-toe Italian footwear during the workday, they are conscious of their personal performance, and the performance of their tools, in comparison to those of their peers. It’s a guy thing, something women think they understand because they have similar tendencies in other areas, but rarely do. This performance is difficult to ascertain unless one is working side by side with one’s peers, so it is human nature to make indirect judgements about performance by observing the quality and condition of a fellow worker’s tools.

Of course, one casually notices the brand of chisel or plane a fellow craftsman is using. Next, if it can be done without being rude (sometimes a difficult thing to accomplish), one examines the fellow workman’s tool’s cutting edge and its sharpness because this tells much about his character and skill (chisels are terrible gossips, you see). Such a close examination may not be possible, but one can usually examine the finish left by his plane and crispness and precision of his chisel cuts.

But more than plane or chisel, the tool that is always visible to others during the workday is the craftsman’s hammer comprised of the head forged by the blacksmith, and the handle made by the craftsman himself. The quality of this combination tells Japanese craftsmen much about the man that owns and uses the tool. A hand-forged head by Kosaburo or Hiroki with a graceful, professional-grade handle made by the owner, even if it is dinged through years of hard use, will be noticed by those with eyes to see for decades, even generations.

Among the Japanese professional woodworkers your humble servant knows well, most of whom ceased getting older long ago, a highly-decorated expensive gennou head is thought to be a gaudy, obvious plea for attention, and in poor taste, like wearing a purple sequined silk suit and Jimmy Choo 8″ gold lame stilettos to the hardware store (best saved for the New Years party anyway, you sexy beast). A plain head by Hiroki or Kosaburo, on the other hand, is understated tasteful evidence of a serious craftsman that appreciates tradition and places quality first. Very much a wabi sabi kinda thing.

And finally, a quality hand-forged head is a lifetime tool, one that won’t wear out or break. The handle may be damaged and wear out over time and need to be replaced, but such wear and tear is unavoidable if the tool is actually used, like a good pair of workboots. But the handle made for a quality head will last longer and be much much easier and quicker to replace. To the professional focused on turning his time into money, this is not an insignificant consideration.

A mass-produced factory head, by comparison, simply won’t work as well. It is of course neither high-quality, unique, nor a lifetime heirloom tool. It isn’t pleasing to the owner’s eye nor impressive to his fellow workers. It is a consumable, expedient tool, the sort of thing a craftsman does not want himself to become.

Conclusion

A high-quality head combined with a handle that fits your body will accomplish more work more precisely with less mental concentration and physical effort. It will become a lifetime friend and a source of satisfaction boosting your confidence. It will be relatively easy to make replacement handles for during your lifetime, and those handles will stay tighter longer. It will tell those who see it that you are serious, no-nonsense craftsman who understands true quality and prefers understated elegance.

If you take pride in your tools, appreciate heirloom value, don’t want to waste time trying to rework sow’s ears into silk purses that smell piggy, and are not inclined to invite psychiatrists to rummage around in your head, then a hand-forged gennou head is worth owning, in the opinion of your most humble and obedient servant.

In the next post in this swashbuckling adventure on the high seas we will try to dispel some rumors about laminated gennou heads.

YMHOS

The following link is to a folder containing pricelists and photos of most of our products. If you have questions or would like to learn more, please use the form located immediately below titled “Contact Us.”

Please share your insights and comments with everyone by using the form located further below labeled “Leave a Reply.” We aren’t evil Google, facist facebook, thuggish Twitter, or a US Congressman’s Chinese girlfriend and so won’t sell, share, or profitably “misplace” your information. May puppies all hate me if I lie.

Leave a comment