The more one gardens, the more one learns; And the more one learns, the more one realizes how little one knows.

Vita Sackville-West

This post is definitely different from my previous ones. It will deal with buildings and earthquakes. It has nothing to do with wood or woodworking tools.

ingenhovenarchitects.jpg)

In my day job I am an executive with a large international Real Estate and Construction Project Management company in Tokyo, Japan. Without going into details that might violate non-disclosure agreements, my job involves managing all aspects of real estate acquisition and leasing, as well as the design, procurement, and construction of commercial and industrial projects. Mostly for non-Japanese Clients.

The photo above is one project I am involved in on behalf of a Client.

Tokyo is an expensive place to set up operations, and the real estate and construction processes are especially confusing for foreign companies. Ergo, the need for me and my teams.

My educational background is structural engineering, focused on seismic-resistant design. All of my Clients are very concerned about the earthquakes Tokyo experiences almost daily. There will be several magnitude 4~5 quakes here each year. This tends to keep people focused.

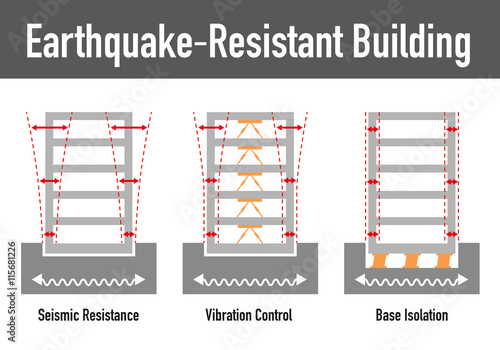

My point is that earthquakes are a constant threat taken seriously and for good reason. Accordingly, to one degree or another as building codes and Owners require, all buildings incorporate aseismic design features.

I have worked on buildings with expensive full-blown base isolation using rubber bridge bearings and hydraulic dampers similar to giant automotive shock absorbers, and other systems designed to dissipate damaging earthquake forces, but what I would like to show you today is a “slip-joint brace damper” just installed at a building near my office located in Marunouchi near the Imperial Palace (not the building in the perspective rendering above).

Notice how deep the beams are, and how thick the steel is. Although they don’t show up well in the photo, the columns too are massive. Much heavier than is typical in Western structures. I love Japanese structural steel!

I am not involved in this high-rise building, but a contractor I have used in the past named Obayashi Corporation 大林組 is the General Contractor. I was able to snap this picture of Obayashi’s jobsite while walking to my office from the subway station last week during a rare moment when the front gate was open and nothing was in the way.

The white columns and diagonal braces are the key to this seismic damping system.

The white paint is a fire-resistant intumescent coating designed to protect the steel from heat during a fire. Structural steel is very weak when exposed to fire, much more so than wood or concrete, so this sort of protection, while expensive, is necessary. The rest of the structural steel will be sprayed with a thicker, less-expensive and less-durable fire-resistant coating of one variety or another.

The diagonal braces in the photo are basically two steel plates bolted together face to face. The bolt holes are slotted to allow the bolts and plates to slip past each other when subjected to a certain amount of force.

The plates and bolts are contained in a steel pipe filled with high-friction oil to prevent the brace from buckling, prevent corrosion, and ensure the coefficient of friction between the plates/bolts remains constant for many decades in the future.

As the ground moves during an earthquake, the building moves with it, and the structural steel sways. The rectangular opening framed by connected beams and columns changes shape, becoming longer or shorter in the diagonal directions. Braces resist this “racking” movement.

As the plates and bolts in these dampers slip past each other, a great deal of friction is created converting the earthquake’s energy to heat, slowing down the racking motion, and controlling the harmonic vibration of the entire building.

Although fixed-length braces are common in lighter, shorter structural frames, they are not usually a good thing in large structural steel frames because they tend to behave erratically and fail suddenly. This can be inconvenient.

The steel frame must be made strong enough without fixed-length bracing to absorb these forces without failing anyway to make a reliable structure. But if the frequency of the building’s movement back and forth and side to side begins to match that of the ground, then something called “resonance” can occur potentially doubling the forces acting on the building, forces powerful enough to suddenly and violently bend, break and topple the building. This can be inconvenient.

An alternative to this sort of damping brace system is the more expensive “Base Isolation System”

So why would anyone use an expensive system like base isolation?

Base isolation allows the entire building, from its base up, to move opposite the ground motion in the horizontal direction, reducing the induced sway, racking, and damage to its interior and systems and equipment stored inside. This level of protection is necessary if the building must continue to function uninterrupted immediately after a large earthquake. Hospitals, R&D centers, Data Centers and other sensitive buildings with lots of expensive equipment that must be kept running no matter what are often worth the cost of base isolation systems.

But in the case of an office building like the one in the photo, the owner decided some interior damage, and the business interruption repairs would entail after the earthquake, would be acceptable.

The photos below show two components of the typical base-isolation system.

I hope you found this post interesting. Let me know if you want to see more stuff like this.

YMHOS

If you have questions or would like to learn more about our tools, please use the questions form located immediately below. Please share your insights and comments with everyone in the form located further below labeled “Leave a Reply.” Your information will remain confidential (we’re not evil Google or incompetent facebook).

great combination of information, clearly expressed, and striking photos that show exactly what you are talking about – thanks!

LikeLike

Thanks, IP! You have a great blog.

LikeLiked by 1 person

Very interesting post, Stan! Thank you for the detailed write up on this topic. I don’t have much to add, but certainly enjoyed reading this.

LikeLiked by 1 person

Thanks, Brain. I fear it may be deadly dull.

LikeLike

Stan,

Very interesting and informative. I’m curious about the track record of these measures. Sounds like small quakes are common, but have they been severely tested with “the big one”, that is, quakes 7.5+? If so, how have the structures fared? Is there a limit in terms of scale which these measure are effective? For instance, if a magnitude 9 quake hit Tokyo, what would be the expected result? Not living there, perhaps it has happened and these measure are perfected based on that experience.

LikeLike

Pete:

Good question.

Yes, excellent track record. Some base isolation buildings endured the Tohoku earthquake in March 2011 of magnitude (in some locations) 9.1, the largest ever recorded in Japan. It was 7.8+ here in Tokyo. I was at work in a high-rise building when it hit.

Not a single modern building in Tokyo failed. Power outages yes. Tile falling from walls, yes. Old wooden buildings collapsing, yes. But no deaths in base isolated buildings. And damage to equipment was very small.

There is video somewhere comparing the movement of two buildings nearby at the same time the earthquake hit. One had base isolation. Chairs moved around, and water splashed out of fishtanks, but bookshelves did not fall over. The other was a wreck, with ceilings falling, desk overturning, shelves falling on people and printers broken and jumbled. What a mess! If it had been a hospital, all the testing equipment would have been destroyed.

On the other hand, people killed by block walls, old concrete buildings, etc and the tsunami officially totaled 15,897 deaths. I am confident many more died (600+?) due to the nuclear power plant accident, but the Japanese government, and the Japanese press, is concealing those deaths as they were due to the worst environmental disaster resulting from the world’s most incompetent management of nuclear power in human history. Exaggeration? Not even a little.

Anyway, Japan’s seismic design techniques, while expensive, have performed exceptionally well. Perfect? No. But good solutions.

Regards,

Stan

LikeLike

Not dull to me. I live in the Pacific Northwest, where a big Cascadia event is always possible. I also just made my yearly payment for our earthquake insurance.

LikeLiked by 1 person

I pray all the money spent on earthquake insurance never becomes necessary. Stan

LikeLike

Pretty fun stuff. Reminds me of my childhood (dad was a structural engineer hired to rebuild SF after the earthquake).

After the LA earthquake, this stuff is more relevant than ever.

LikeLike

Thanks Matt.

Yes, I agree about the relevance.

Stan

LikeLike

An interesting and timely subject that reveals a little area of construction engineering in this country and around the world. I am curious about the seismic code requirement for family dwellings in the Tokyo area. Thanks for a good article on a little known but very important topic.

LikeLike

Randy, It has been a long time since I have looked into building codes for SFDs in Tokyo. They are not as straight-forward as commercial buildings due to the irregular shapes and smaller sizes. But as I recall, as a result of the Kobe where so many traditional Japanese houses failed so dramatically, the Japanese code has adopted a lot of its critieria and methodology from US. The lighter-weight and inexpensive rigidity provided by 2×4 with plywood shearwalls is valued highly. Not so much in areas hit hard by typhoons where mass is useful.

Even in the case of traditional post&beam construction, code requires a calculated amount of shear walls, and/or bracing with metal connections. Likewise, beam/post/sill/reafter connections must now be connected with rated metal connectors where tension loading or uplift are possible.

The result has been a dramatic reduction in the catastrophic failure of SFDs during earthquakes and typhoons. Only time will tell if they hold up as well over the 80~90 years that weakened the traditional houses in Kobe that collapsed due to heavy tile roofs and rotted post bottoms.

Prefabricated housing has become very popular here. Panasonic is a big player nowadays. LGS frames with ALC panel walls. They look good, have good insulation and air-tightness, go up quickly, and have a better perceived warranty.

If I had the bucks and was going to build a house, however, as a result of my research in past years, I would go with a precast-concrete house. Boring in appearance yes. Twice the price of a standard framed house, yes. Not as easy to meet sesimic code requirements (but of course, still doable). But fires don’t bother them. Typhoons don’t have any impact (if you have widow shutters). And they wade through tsunami easily. I have video of the aftermath of the Tohoku earthquake where entire neighborhoods of hundreds of houses were flattened and sucked out to sea (tremendous loss of life you may recall) by the tsunami but concrete houses (Palcon’s products were one example) suffered broken windows on the grounnd floor, while families rode out the typhoon on the second floor, even after the structure was hit by large fishing boats carried up by the wave.

An interesting subject.

Stan

LikeLiked by 1 person

Thanks for posting, Stan. That diagram for the three types of construction is worth the price of admission. Have you seen this video demonstrating a Chinese temple “model” undergoing base excitation: https://youtu.be/w78Yb_aotH0

LikeLike

Thanks for your kind words. I had not seen the video before. Extremely interesting. I think they overestimate the functional value of the “dogan” (kumimono in Japanese) assemblies located at the top of the columns, but the advantages of a flexible frame are undeniable. The problem with flexible frames arises when the period of the earthquake vibration and that of the structure compliment each other instead of canceling each other out resulting in harmonic vibrations that can double the forces acting on the frame’s connections resulting in catastrophic failure. Plenty of those examples in history too. Modern engineers have more data, examples, and tools for analyzing vibration and designing structures that reduce the potential for harmonic motion, so there is less guesswork involved. Even then, they get it wrong sometimes. Mother nature has huge stick she likes to swing all over the place.

LikeLike